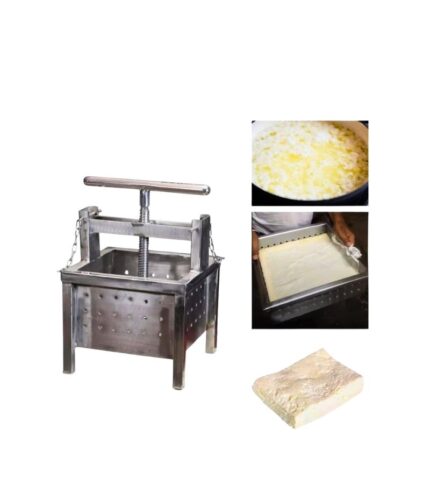

Milk/Water Boiler Dispenser

The Milk/Water Boiler Dispenser is a high-performance and energy-efficient solution designed to provide reliable boiling and dispensing of milk or water across multiple industries, including dairy, food & beverage, pharmaceuticals, and catering. Built with a focus on durability and ease of use, this dispenser ensures consistent temperature control, making it ideal for high-volume operations where precise heating is essential. Whether for large-scale milk pasteurization, boiling water for beverages, or other food processing applications, this equipment plays a crucial role in maintaining product quality and improving operational efficiency.

Product Overview

The Milk/Water Boiler Dispenser is engineered to meet the demanding needs of industries that require quick and efficient heating. Constructed from high-quality stainless steel, it offers superior corrosion resistance and longevity. Its modular design allows for easy integration into existing systems, while its user-friendly interface ensures straightforward operation. Built for heavy-duty use, this dispenser is ideal for continuous operation, allowing users to handle large volumes of liquid without compromising on performance. Its energy-efficient operation reduces utility costs, while the precise temperature control helps avoid overheating and preserves the quality of the liquid being processed.

Technical Specifications

- Material Quality: Premium stainless steel for maximum durability and resistance to corrosion.

- Dimensions: Customizable to fit various installation spaces and operational needs.

- Compliance: Designed in accordance with CE, ISO, and NSF standards for safety and hygiene.

- Temperature Range: Capable of heating liquids to a range of 90°C - 100°C, with precise temperature regulation for consistent results.

- Capacity: Available in multiple sizes to accommodate both small-scale and large-scale operations.

Maintenance Tips

To ensure the Milk/Water Boiler Dispenser operates at peak efficiency, it is recommended to regularly inspect and clean the heating elements, as well as check the seals for any wear or leaks. The stainless steel surfaces should be wiped down after use to prevent buildup and maintain hygiene. Routine maintenance will extend the life of the dispenser, reduce energy consumption, and prevent downtime. Always follow the manufacturer’s guidelines for proper cleaning and maintenance to ensure long-lasting performance and optimal safety.

Key Features and Benefits

- Durability: Constructed from high-grade stainless steel for extended operational life, even in demanding environments.

- Energy Efficiency: Designed to minimize energy consumption while maintaining high performance, reducing operational costs.

- Precision Control: Features a digital control system for exact temperature regulation, ensuring optimal results and reducing product spoilage.

- Low Maintenance: Built with easy-to-clean components to reduce downtime and maintenance costs.

- Safe Operation: Equipped with overheat protection and automatic shut-off features to ensure safety during operation.

Applications

The Milk/Water Boiler Dispenser is an essential tool in industries where reliable heating is crucial:

- Dairy: Used in milk processing and pasteurization to ensure high-quality product output.

- Food & Beverage: Ideal for boiling water for beverages like tea, coffee, or soups, ensuring consistent quality.

- Pharmaceuticals: Supports boiling water for sterilization or other controlled heating processes.

- Catering: Provides reliable boiling and dispensing of liquids for large-scale food preparation in hotels, restaurants, and institutional kitchens.

Reviews

There are no reviews yet.