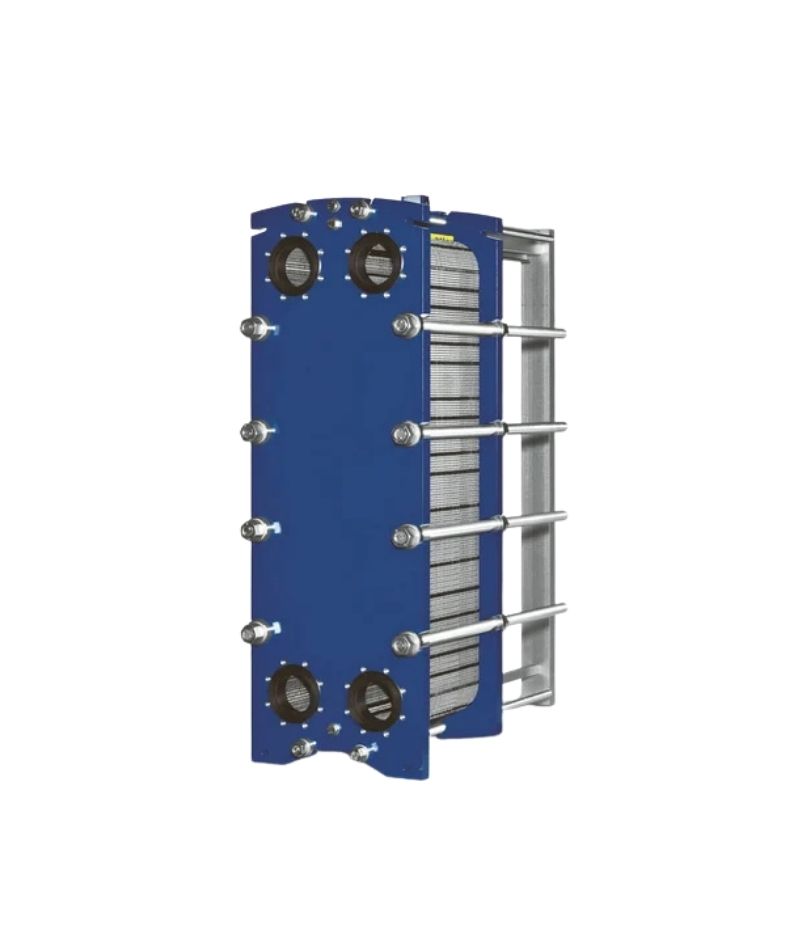

Gasketed Plate Heat Exchanger

The Gasketed Plate Heat Exchanger is a highly efficient and versatile solution designed for a wide range of industries, including chemical processing, pharmaceuticals, dairy, automotive, and food & beverage. Built to meet the stringent demands of modern industrial applications, this heat exchanger offers exceptional thermal efficiency, durability, and easy maintenance.

Product Overview

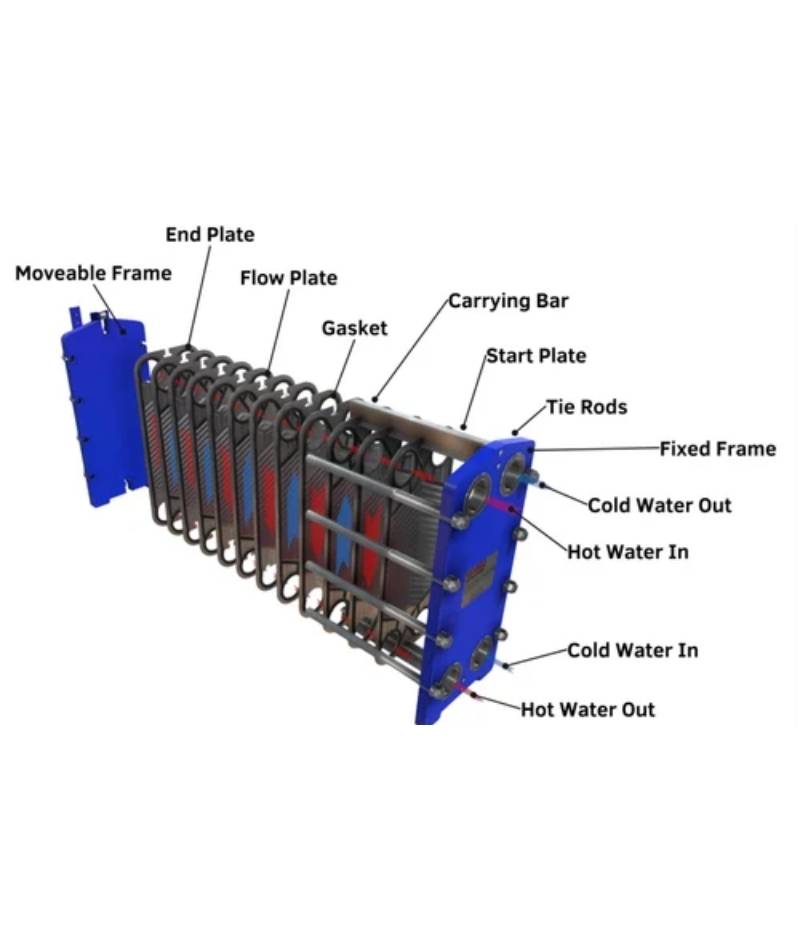

This heat exchanger is specifically engineered to provide high-performance heat transfer in a compact footprint. The unique gasketed design allows for easy assembly and disassembly, making it ideal for systems that require regular cleaning or capacity adjustments. It effectively transfers heat between liquids or gases without allowing them to mix, thanks to the robust gaskets that seal each plate.

Technical Specifications

- Material Quality: Available in high-grade stainless steel and titanium for superior corrosion resistance.

- Dimensions: Customized plate sizes and configurations to meet specific flow rates and pressure requirements.

- Compliance: Designed in adherence to ASME, ISO, and CE standards to ensure safety and reliability.

- Temperature & Pressure: Handles temperatures up to 180°C and pressures up to 25 bar, depending on the model and configuration.

Maintenance Tips

Regular inspection of the gaskets and periodic cleaning of the plates ensure optimal performance. Easily accessible design allows for quick disassembly and reassembly, reducing maintenance time.

Key Features and Benefits

- High Efficiency: The plate design maximizes the surface area, enabling rapid heat exchange while reducing energy costs.

- Durable Construction: Made with premium materials that withstand harsh industrial environments, ensuring a longer service life.

- Modular and Flexible: Easily scalable by adding or removing plates, making it adaptable to changing operational needs.

- Cost-Effective: Low maintenance and energy-efficient, reducing overall operational costs.

- Leak-Proof Operation: Advanced gasket technology prevents leakage, maintaining system integrity and minimizing downtime.

Applications

Widely used in cooling and heating applications, this heat exchanger serves essential roles in:

- Chemical and Petrochemical: Ideal for heat recovery, condensation, and reboiling processes.

- Food & Beverage: Ensures safe, hygienic heat transfer for processes such as pasteurization and milk cooling.

- Pharmaceuticals: Efficiently supports processes like temperature-sensitive fluid transfer and sterilization.

- Dairy: Maintains product quality by effectively controlling temperature during milk and cream processing.

Reviews

There are no reviews yet.